.png)

- 19/06/2024

- News - Events

.png)

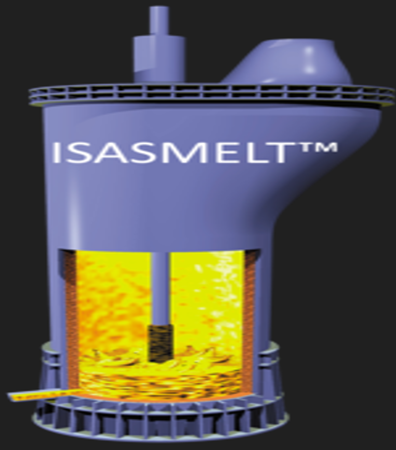

ISASMELT FURNACE, which is an efficient system of smelting process in metallurgical industry, has been applied to Lead, Copper, Nickel, Zinc … Mineral concentrates or materials for recycling are dropped into the tank. The feed materials and chemical components react with the oxigen in the injection gas, resulting in an intensice reaction that made basic metal. ISASMELT is the most advanced technololy and a monoply technology of Glencore Technology – Australia.

The main Isasmelt furnace is an upright-cylindrical shaped steel vessel that is lined with refractory bricks. The refactory bricks to protect affect of heat or chemical attached to shaped steel vessel during operation.

Other systems are mineral feeder system, energy injected system rotate system of Furnace, refine and cooling system, power supplying and digital control system. All systems are assemblied to built up a completed equipment. The mechanical parts were fabicated and machined with very high pecision, all tolerance strickly according to Client technical specification.

Lisemco 5 Mechanical and Construction Joint Stock Company has sucessfully fabricated the main construction, other service system for 02 Isasmelt furnaces and 02 spare furnace’s vessles. The completed system was assemblied before Client’s expert comes for the inspection. From the third of June to the seventh of June the GLENCORE’s technical experts have carried out the assembly inspection and the fuction test at our factory. The assembly works and fuction test practice were done prefectly, all technical parameter met require even some items of product were inovated by LISEMCO 5’s design team to get final product come up more than Client expectation. After the test finished the equipment was disassemblied for painting the full coat before re-assembly, packing and delivery.